Home > Stainless Steel > Stainless Steel 317 and 317L Electropolished Pipes

Irfan Pipes and Tubes, based in Istanbul, Turkey, stands out as a top manufacturer and supplier of **Stainless Steel 317 and 317L Electropolished Pipes**. They specialize in providing high-quality piping solutions for industries that demand exceptional corrosion resistance and smooth, contaminant-free surfaces. Thanks to their state-of-the-art manufacturing facilities and rigorous quality control, the company is committed to delivering electropolished pipes that guarantee durability, hygiene, and long-lasting performance in even the most challenging applications. These pipes are commonly found in the chemical, petrochemical, pharmaceutical, and food processing sectors. Irfan Pipes and Tubes prides itself on timely deliveries and customer satisfaction, making them a trusted partner for critical industrial needs.

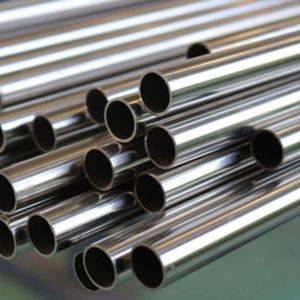

Stainless Steel 317 and 317L Electropolished Pipes are austenitic stainless steels, typically containing around 18–20% chromium, 11–15% nickel, and 3–4% molybdenum. The 317L variant features a lower carbon content, which enhances its weldability and minimizes carbide precipitation. The electropolishing process not only eliminates surface imperfections but also boosts corrosion resistance and results in a smooth, hygienic finish. Mechanically, these pipes showcase high tensile strength, good toughness, and outstanding resistance to pitting and crevice corrosion, especially in chloride-rich environments. These characteristics make Stainless Steel 317 and 317L Electropolished Pipes perfect for applications that require both mechanical reliability and superior surface quality.

| Specifications | : | ASTM A/ASME SA249/A269/A270 |

| Dimensions | : | ASTM, ASME, and API |

| SS 317 and 317L Pipes Size | : | 1/8″NB TO 30″NB IN |

| Thickness | : | 1mm to 20mm, SCH 5/5S, 10/10S, 20/20S, 40/40S, 80/80S, 120/120S, 160/160S as per ANSI B36.19/36.10 |

| Finish | : | BA Finish inside and outside, Electropolished finish inside and outside |

| Type | : | Electropolished Pipes & Tubes |

| Form | : | Round, Square, Rectangular, Hydraulic Etc |

| Length | : | Up to 6 meters, custom cut lengths |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Fe |

| SS 317 | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 18.00 – 20.00 | 3.00 – 4.00 | 11.00 – 15.00 | 57.845 min |

| SS 317L | 0.035 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 18.00 – 20.00 | 3.00 – 4.00 | 11.00 – 15.00 | 57.89 min |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 7.9 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Choosing Stainless Steel 317 and 317L Electropolished Pipes from Irfan Pipes and Tubes guarantees excellent corrosion resistance, high strength, and durability. Designed for diverse industrial applications, it delivers reliable performance in tough environments while maintaining competitive pricing for cost-effective solutions.

Irfan Pipes and Tubes, a leading manufacturer and supplier of Stainless Steel 317 and 317L Electropolished Pipes in Istanbul, Turkey, offers a comprehensive range of high-quality pipes and tubing suitable for various industrial applications. Our extensive inventory and commitment to exceptional service make us a trusted choice for regional products.

| STANDARD | WERKSTOFF NR. | UNS | JIS | EN |

| SS 317 | 1.4449 | S31700 | SUS 317 | – |

| SS 317L | 1.4438 | S31703 | SUS 317L | X2CrNiMo18-15-4 |

We offer custom sizes for Stainless Steel 317 and 317L Electropolished Pipes to meet your specific needs. Our dedicated team at Irfan Pipes and Tubes provides tailored solutions for all your piping and tubing requirements. For more information, contact us at sales@irfanpipes.com.

In various industries that need corrosion-resistant, hygienic, and durable piping solutions, Stainless Steel 317 and 317L Electropolished Pipes are a go-to choice. In chemical and petrochemical plants, they are utilized for process piping, reactors, and heat exchangers that come into contact with aggressive chemicals. The pharmaceutical and food processing sectors rely on them for sanitary pipelines, clean-in-place systems, and equipment where smooth, contaminant-free surfaces are crucial. Additionally, they are used in marine applications, including seawater handling systems and desalination plants.

©2024 Irfan Pipes and Tubes . All Rights Reserved.