Home > Stainless Steel > Stainless Steel 310 and 310S Seamless Pipes

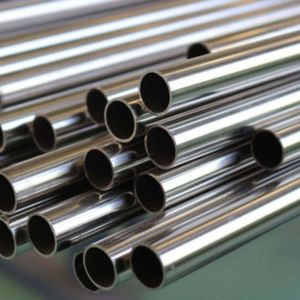

Irfan Pipes and Tubes, an Istanbul, Turkey-based company, is a trusted manufacturer and supplier of stainless steel 310 and 310S seamless pipes, recognized for providing high-quality products that adhere to rigid industry standards. They are commonly used in applications that demand superior heat resistance and corrosion performance, including power generation, petrochemical, and furnace production. Irfan Pipes and Tubes maintains precision manufacturing and strict quality control to deliver long-lasting seamless pipes capable of functioning efficiently under conditions of extreme temperature and corrosivity.

Seamless pipes of stainless steel 310 and 310S are austenitic alloys with high contents of 24–26% chromium and 19–22% nickel, exhibiting superior oxidation and corrosion resistance at high temperatures. The 310S type contains less carbon (up to 0.08%) than 310, with better resistance to carbide precipitation and sensitization when welding or exposed to high temperature. Both materials have tensile strengths of usually between 515 and 700 MPa, accompanied by good toughness and ductility. Their high nickel and chromium content gives them good mechanical strength and resistance to scaling when used up to 1150°C.

Range : 6NB to 1200NB

Outer Diameter : 1/8″ NPS to 12″ NPS

Thickness : 0.6 mm to 12.7 mm

Schedules : SCH. 5, 10, 20, 30, 40, 60, 80, 100, 120, 140, 160, XXS.

Length : Single Random, Double Random & Cut Length

Specifications : ASTM A312 / ASTM SA312

Types : Round, Square, Rectangle, Hydraulic, Honed Tubes

End : Plain End, Beveled End

| STANDARD | UNS | WERKSTOFF NR. |

| SS 310 | S31000 | 1.4841 |

| SS 310S | S31008 | 1.4845 |

| Ni | 19 – 22 | 19 – 22 |

| Fe | Balance | Balance |

| Cr | 24 – 26 | 24 – 26 |

| C | 0.25 max | 0.08 max |

| Si | 1.50 max | 1.50 max |

| Mn | 2 max | 2 max |

| P | 0.045 max | 0.045 max |

| S | 0.030 max | 0.03 max |

| Grade | 310 | 310S |

| Tensile Strength (MPa) min | 515 | 515 |

| Yield Strength 0.2% Proof (MPa) min | 205 | 205 |

| Elongation (% in 50mm) min | 40 | 40 |

| Hardness | ||

| Rockwell B (HR B) max | 95 | 95 |

| Brinell (HB) max | 217 | 217 |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Choosing Stainless Steel 310 and 310S Seamless Pipes from Irfan Pipes and Tubes ensures high quality and durability, as these tubing offer excellent corrosion resistance and strength. Our commitment to exceptional service and reliable delivery guarantees customer satisfaction across various industrial applications. Our expertise in stainless steel products ensures you receive a top-tier solution tailored to your needs.

Irfan Pipes and Tubes, one of the largest suppliers of Stainless Steel 310 and 310S Seamless Pipes in Istanbul, Turkey, offers a comprehensive range of high-quality pipes and tubes suitable for various industrial applications. Their extensive inventory and commitment to exceptional service make them a go-to choice for stainless steel products in the region.

| Grade | UNS No | Old British | Euronorm | Swedish SS | Japanese JIS | ||

| BS | En | No | Name | ||||

| 310 | S31000 | 310S24 | – | 1.4841 | X15CrNi25-20 | – | SUH 310 |

| 310S | S31008 | 310S16 | – | 1.4845 | X8CrNi25-21 | 2361 | SUS 310S |

| Grade | Density (kg/m3) | Elastic Modulus (GPa) | Mean Coefficient of Thermal Expansion (m/m/0C) | Thermal Conductivity (W/m.K) | Specific Heat 0-1000C (J/kg.K) | Electrical Resistivity (n.m) | |||

| 0-100°C | 0-315°C | 0-538°C | at 100°C | at 500°C | |||||

| 310 and 310S | 7750 | 200 | 15.9 | 16.2 | 17.0 | 14.2 | 18.7 | 500 | 720 |

Yes, we offer custom sizes for Stainless Steel 310 and 310S Seamless Pipes to meet your specific requirements. Our team at Irfan Pipes and Tubes is committed to providing tailored solutions for all your Piping & tubing needs. For more details, contact us at sales@irfanpipes.com.

Stainless steel 310 and 310S seamless tubes are best suited for high-temperature exposure and corrosive environments applications. They are widely employed in furnace equipment, heat exchangers, kiln linings, and gas turbine parts. The petrochemical sector utilizes these tubes in high-temperature process units, while power plants utilize them for use in superheater and reheater tube. They also find usage in the food and drug industries when there is a need for high temperature and corrosion resistance. Their high weldability and stability to heat make them capable of being used under severe environments that require extended service life and sound performance.

©2024 Irfan Pipes and Tubes . All Rights Reserved.