Home > Nickel Alloy > Nickel Alloy Boiler Tubing

Irfan Pipes and Tubes, Istanbul, Turkey, is a well-established producer and supplier of high-performance nickel alloy boiler tubing to industries requiring outstanding thermal and corrosion resistance. Specializing in precision manufacture and complying with global standards, the company supplies tubing solutions for high-pressure and high-temperature applications. Nickel alloy boiler tubes from Irfan Pipes and Tubes are relied upon by power plants, refineries, and chemical processing plants for durability, safety, and uninterrupted service. The company achieves long service life and safe operation in demanding systems through sophisticated manufacturing processes and rigorous quality control.

Nickel alloy boiler tube is produced from high-nickel-alloyed materials, usually containing added elements like chromium, molybdenum, and iron to increase strength, resistance to oxidation, and thermal stability. The tubes have excellent mechanical properties, with tensile strength usually higher than 600 MPa and high stress corrosion cracking, pitting, and crevice corrosion resistance. Nickel alloy boiler tube retains its strength at over 800°C, which makes it suitable for applications involving high-efficiency heat transfer. Seamless construction also provides the tube with pressure strength, uniform thickness, and resistance to thermal cycling or hostile media failure.

| Nickel Pipe sizes range | 1/8”NB to 30”NB (Nominal Bore Diameter, ie the inner diameter of the pipe) |

| Manufacturer of | Seamless, Welded, Electric Resistance Welded (ERW), Fabricated, or LSAW |

| Form of | Round, Hydraulic, Rectangular, or Square |

| Marking | All Nickel Alloy pipes & tubes are marked as: Manufacturer Name, Standard, Grade, Thickness, OD, Length, Heat No. (Or according to the customer’s request.) |

| Pipe Schedule | SCH5, SCH10, SCH10S, SCH20, SCH30, SCH40, SCH40S, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS |

| Pipe End | POE, TOE, TBE, BOE, BOE, PBE, BLE, BSE, BBE, BE, Plain End, Beveled End, and Treaded |

| Nickel Alloy Tubes | Ni | C | Mo | Mn | Si | Fe | P | S | Cu | Cr |

|---|---|---|---|---|---|---|---|---|---|---|

| Alloy 200 Tube | 99.0 min | 0.15 max | – | 0.35 max | 0.1 max | 0.4 max | – | 0.01 max | 0.25 max | – |

| Alloy 201 Tube | Balance | 0.15 max | – | 0.35 max | 0.35 max | 0.40 max | – | 0.01 max | 0.25 max | – |

| Nickel Based Alloys | Density | Melting Point | Yield Strength (0.2%Offset) | Tensile Strength | Elongation |

| Alloy 200/ 201 Tube | 8.9 g/cm3 | 1446 °C (2635 °F) | Psi – 21500 , MPa – 148 | Psi – 67000 , MPa – 462 | 45 % |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Choosing Nickel Alloy Boiler Tubing from Irfan Pipes and Tubes ensures high quality and durability, as these tubing offer excellent corrosion resistance and strength. Our commitment to exceptional service and reliable delivery guarantees customer satisfaction across various industrial applications. Our expertise in nickel alloy products ensures you receive a top-tier solution tailored to your needs.

Irfan Pipes and Tubes, one of the largest suppliers of Nickel Alloy Boiler Tubing in Istanbul, Turkey, offers a comprehensive range of high-quality pipes and tubes suitable for various industrial applications. Their extensive inventory and commitment to exceptional service make them a go-to choice for nickel alloy products in the region.

Yes, we offer custom sizes for Nickel Alloy Boiler Tubing to meet your specific requirements. Our team at Irfan Pipes and Tubes is committed to providing tailored solutions for all your Piping & tubing needs. For more details, contact us at sales@irfanpipes.com.

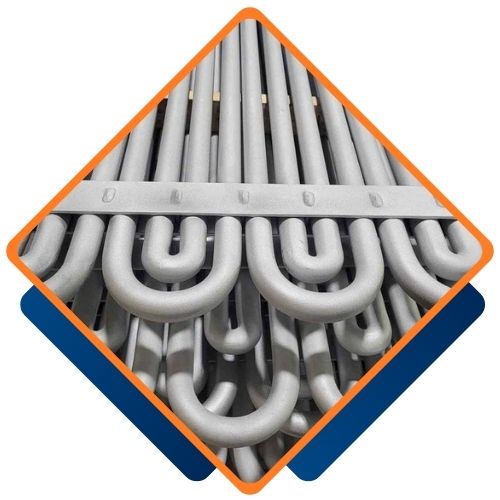

Nickel alloy boiler tube finds widespread application in industries that demand consistent heat transfer in harsh conditions. Used in power generation, particularly in supercritical and ultra-supercritical boilers, for use in superheaters, reheaters, and water walls, this tubing is also used by the chemical and petrochemical industries in waste heat recovery units, reformers, and thermal oxidizers where there is frequent exposure to corrosive gas and high temperatures. It is also being applied to marine boilers, pulp and paper treatment, and nuclear power plants. The resistance of the tubing to oxidation, thermal fatigue, and chemical attack makes it unavoidable when safe and effective boiler operation is needed.

©2024 Irfan Pipes and Tubes . All Rights Reserved.