Home > Incoloy > Incoloy ERW Pipes

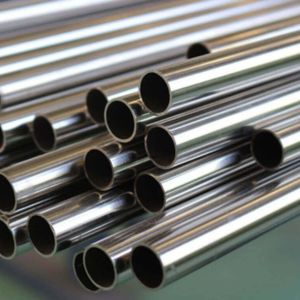

Irfan Pipes and Tubes, based in Istanbul, Turkey, is a well-respected manufacturer and supplier of **Incoloy ERW Pipes**. They provide top-notch piping solutions for industries that demand strength, durability, and outstanding resistance to high-temperature corrosion. Using advanced Electric Resistance Welding (ERW) techniques and adhering to international standards, these pipes guarantee excellent dimensional accuracy, smooth internal surfaces, and dependable mechanical properties. Incoloy ERW Pipes find their place in various sectors, including chemical, petrochemical, marine, and power generation industries. Irfan Pipes and Tubes is dedicated to delivering premium-grade products promptly for critical industrial applications around the globe.

Incoloy ERW Pipes are made from nickel-iron-chromium alloys, with different amounts of molybdenum, copper, titanium, or aluminum added based on the specific grade. This special blend offers remarkable resistance to oxidation, carburization, sulfidation, and stress corrosion cracking, even in harsh, high-temperature settings. On the mechanical side, they boast high tensile and yield strength, excellent creep and rupture resistance, and superior toughness. The ERW manufacturing process ensures strong weld integrity, consistent wall thickness, and durability, making these pipes a reliable choice for long-term use in challenging conditions.

| Incoloy 800 Pipe International Specification | ASTM B407, ASTM B514, ASTM B829, ASTM B515, ASTM B775, ASTM B751 BS3 3074NA15, ISO 6207, DIN 17459, VdTüV 412 & 434 |

| Standard Specification | ASME, ASTM, AISI, AMS, JIS, EN, SAE, DIN, NF, TOCT, DS, DTD, GB |

| Incoloy 800 ERW Pipe Size |

|

| Incoloy Alloy 800 Pipe WT | SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS |

| Werkstoff 1.4876 Incoloy Pipe manufacturing techniques | Seamless / ERW / EFW/ Welded / Fabricated / CDW/ LSAW/ Seam-Welded / Redrawn |

| Origin of Incoloy 800 Din 1.4876 pipe material | Indian, European, Korean, Japanese |

| Incoloy Alloy 800 Pipe End Types |

|

| Form | Round, Square, Rectangular |

| Incoloy N08800 Pipe Length | Single Random, Double Random & Required Length End: Plain End, Beveled End, Treaded |

| UNS N08800 Incoloy 800 Pipe Delivery Condition | Annealed and Pickled, Hot Finished, Polished, Bright Annealed, Cold Drawn |

| Incoloy 8800 Pipe Packing |

|

| Grade | Mn | Al-Ti | C | Ni | Fe | Si | Cr | S | |

| Incoloy ERW Pipe | minimum | – | 0.015 | 0.005 | 30.00 | 39.05 | – | 19.00 | – |

| maximum | 1.05 | 0.060 | 0.01 | 35.00 | – | 1.00 | 23.00 | 0.0015 | |

| Element | Yield Strength 0.2% Proof (MPa) min | Tensile Strength (MPa) min | Elongation (% in 50mm) min | Hardness | |

| Brinell (HB) max | Rockwell B (HR B) max | ||||

| Inconel | MPa –205, Psi – 30,000 | MPa – 520, Psi – 75,000 | 30 | – | – |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Choosing Incoloy ERW Pipes from Irfan Pipes and Tubes ensures superior quality and durability, offering outstanding corrosion resistance and high strength. Our dedication to delivering exceptional service and reliable products guarantees customer satisfaction across a wide range of industrial applications. With our expertise in Incoloy solutions, you can trust us to provide a top-tier, customized piping solution that meets your specific requirements.

Irfan Pipes and Tubes, one of the largest suppliers of Incoloy ERW Pipes in the Istanbuls, Turkey. Offers a wide range of high-quality pipes and tubes designed for various industrial applications. Their extensive inventory and dedication to exceptional service make them a trusted choice for Incoloy products in the region, delivering reliable solutions to meet diverse project requirements.

Yes, we provide custom sizes for Incoloy ERW Pipes to meet your specific requirements. At Irfan Pipes and Tubes, our team is dedicated to delivering tailored solutions for all your piping and tubing needs. For more information, please contact us at sales@irfanpipes.com.

Incoloy ERW Pipes are widely utilized in industries that require dependable performance in corrosive and high-temperature environments. In chemical and petrochemical plants, they are essential for process piping, heat exchangers, and equipment that face acidic and oxidizing conditions. Power generation facilities rely on them for superheaters, reheaters, and boiler systems due to their impressive creep resistance. The marine and offshore sectors use these pipes for seawater piping, condensers, and other applications exposed to chloride-rich environments. Additionally, they are found in oil and gas, aerospace, and industrial furnace systems, where strength, longevity, and resistance to environmental degradation are crucial.

©2024 Irfan Pipes and Tubes . All Rights Reserved.