Home > Stainless Steel > Stainless steel 310H Welded Tubing

Irfan Pipes and Tubes, based in Istanbul, Turkey, stands out as a leading manufacturer and supplier of Stainless Steel 310H Welded Tubing. They specialize in providing top-notch tubing solutions that are perfect for high-temperature and corrosive environments. Crafted with precision and adhering to strict quality standards, this welded tubing boasts impressive oxidation and corrosion resistance while ensuring strength and durability even under thermal stress. You’ll find Stainless Steel 310H Welded Tubing widely utilized in power generation, chemical processing, and industrial furnace applications. Irfan Pipes and Tubes has built a reputation for delivering reliable, efficient, and long-lasting products that meet international standards, guaranteeing optimal performance in challenging industrial settings.

Stainless Steel 310H Welded Tubing is a high-carbon austenitic stainless steel that contains 24–26% chromium, 19–22% nickel, and a controlled carbon content to boost creep and tensile strength at elevated temperatures. It excels in resisting oxidation, high-temperature corrosion, and thermal stress. Its mechanical properties include a minimum tensile strength of 515 MPa, yield strength of 205 MPa, and an elongation of 40%. Thanks to its excellent weldability, toughness, and thermal stability, Stainless Steel 310H Welded Tubing ensures dependable performance in demanding industrial operations where long-term durability and strength are crucial.

| 310H Stainless Steel Tube Finish | Polished, BA (Bright & Annealed),AP (Annealed & Pickled), MF |

|---|---|

| Stainless Steel 310H Tube Standards | ASTM A213,ASTM A269, ASTM A249,ASME SA213,ASME SA269, ASME SA249, NACE MR0175/ISO 15156, PED 97/23/EC,EN 10216-5 TC1 / TC2, AD 2000 |

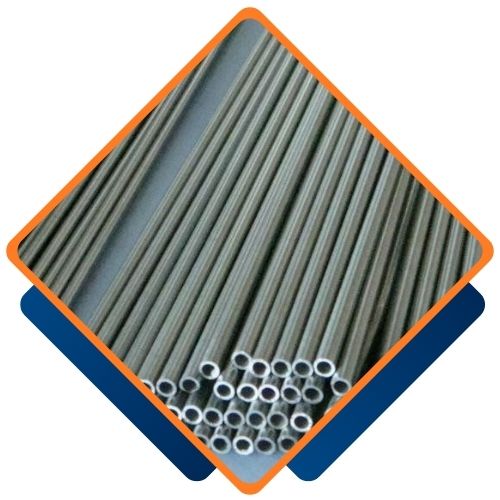

| Stainless Steel 310H Seamless Tube Size | 3.35 mm OD To 101.6 mm OD |

| 310H stainless steel tubing End | Plain End, Beveled End, Treaded, Ends are suitable for orbital welding |

| Marking | All 310H Stainless Steel tubes are marked as follows: Standard, Grade, OD, Thickness, Length, Heat No. (Or according to the customer’s request.) |

| Stainless Steel 310H Welded Tube Size | 6.35 mm OD To 152 mm OD |

| Stainless Steel 310H tubing wall thickness | 0.020″ –0.220″, (special wall thicknesses available) |

| Stainless Steel 310H tube Form | Straight or ‘U’ bent Tubes, Round,Boiler, Coil , LSAW Tubes, Square, Hydraulic, Rectangular, Hollow Etc. |

| Stainless Steel 310H Tube Type | EFW, Seamless , Fabricated, ERW, Welded |

| SS 310H tube Length | Single Random , Standard & Cut length , Double Random |

| Non-Electropolished | (CFOS) Cleaned for Oxygen Grade Service or Corrosive Systems, (BA) Bright Annealed or (AP) Annealed & Pickled for High-Purity |

| I.D. Surface Finish Options | 5, 7 & 10 µin. Ra |

| 310H stainless steel tubing Testing & Inspection | Visual inspection • Surface roughness measurement • Helium-leak testing • Scanning Electron Microscopy (SEM) • Auger Electron Microscopy (AES) • Election Spectroscopy for Chemical Analysis (ESCA or XPS) • Particle testing • Moisture testing |

| Tolerances | In accordance with: ASTM: A269 & A632, JIS: G 3459 |

| 310H stainless steel tubing Test Certificate | Laboratory Test Certificate from Govt. Approved Lab. Manufacturer Test Certificate according to EN 10204 3.1 B Under Third Party Inspection |

| Electropolished | (EP) Electropolished for Ultra High Purity Systems |

| 310H stainless steel tubingApplication | Oil Tube , Boiler and Heatexchange , Gas Tube, Fluid Tuber |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | |

| 310H | min. | 0.04 | – | – | – | – | 24.0 | – | 19.0 | – |

| max. | 0.10 | 2.0 | 1.0 | 0.045 | 0.030 | 26.0 | 21.0 | – | ||

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min | Hardness | |

| Rockwell B (HR B) max | Brinell (HB) max | ||||

| 310H | 515 | 205 | 40 | 95 | 217 |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Choose Stainless Steel 310H Welded Tubing from Irfan Pipes and Tubes for exceptional corrosion resistance, superior strength and excellent durability. Ideal for a variety of industrial applications it provides outstanding performance in harsh environments. With precision manufacturing and quality assurance, we ensure reliable and durable tubing solutions.

Irfan Pipes and Tubes is the largest supplier of Stainless Steel 310H Welded Tubing in Istanbul, Turkey. Known for its high-quality products. We offer superior corrosion resistance, strength, and durability. Trusted by industries worldwide they provide reliable precision-engineered tubing for various applications and project needs.

| Grade | UNS No | Old British | Euronorm | Swedish SS | Japanese JIS | ||

| BS | En | No | Name | ||||

| 310H | S31009 | – | X5CrNi18-10 | 2332 | SUS 310H | ||

Yes, Irfan Pipes and Tubes offer large custom designs for Stainless Steel 310H Welded Tubing. With design, wall thickness and length. Their adjustable options ensure the tubing meets specific application requirements. This flexibility makes it more efficient and reliable for different industries and environments. For more details, contact us at sales@irfanpipes.com.

This tubing is extensively used in industries that require high-temperature and corrosion-resistant solutions. You’ll often find it in furnaces, heat exchangers, boilers, superheaters, and thermal processing equipment. Chemical and petrochemical plants rely on it for transporting hot gases and corrosive fluids. Additionally, the marine, aerospace, and metallurgical industries benefit from its high-temperature stability and durability. With its outstanding mechanical properties, oxidation resistance, and long service life, Stainless Steel 310H Welded Tubing is the go-to choice for critical applications.

©2024 Irfan Pipes and Tubes . All Rights Reserved.