Home > Stainless Steel > Stainless Steel Welded Pipes

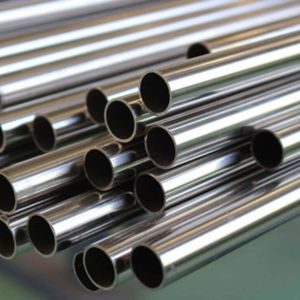

Irfan Pipes and Tubes, a well-respected manufacturer and supplier based in Istanbul, Turkey, focuses on providing high-performance Stainless Steel Welded Pipes for industries around the globe. Crafted with precision engineering and cutting-edge welding techniques, these pipes are celebrated for their durability, resistance to corrosion, and precise dimensions. The company adheres to stringent international quality standards, ensuring that every supply is reliable and consistent. In high demand across sectors like construction, petrochemicals, food processing, pharmaceuticals, water treatment, and power generation, Irfan’s Stainless Steel Welded Pipes promise a long service life, exceptional strength, and cost-effectiveness, making them the go-to choice for critical applications worldwide.

Stainless Steel Welded Pipes are made from top-quality grades like 304, 304L, 316, and 316L, which include iron, chromium (18–20%), nickel (8–12%), and molybdenum (2–3% in 316/316L). This carefully balanced composition provides excellent corrosion and oxidation resistance, along with impressive strength. They showcase remarkable tensile and yield strength, good ductility, and outstanding toughness across a range of temperatures. The smooth internal finish boosts flow efficiency while resisting scaling and stress corrosion cracking. These pipes maintain a consistent wall thickness, weld integrity, and mechanical stability, making them dependable for both moderate and challenging environments.

| Dimensions | ASTM, ASME and API |

| Specifications | ASTM A312, ASTM A249, ASTM A213, ASTM A268, ASTM A269, ASTM A270, ASTM A778 |

| Schedule | SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS |

| Type | ERW / Welded / Fabricated / LSAW Pipes |

| Grades | 304, 304L, 304H, 321H, 321, 316, 316L, 316Ti, 310S, 347, 347H, UNS31803 Duplex |

| Form | Round, Square, Rectangular, Hydraulic Etc |

| Size | 1/8” NB to 36” NB, 1/4” OD to 36” OD sizes stainless steel welded tubes also available |

| Length | Single Random, Double Random & Cut Length. |

| Thickness | 1mm to 20mm, SCH 5/5S, 10/10S, 20/20S, 40/40S, 80/80S, 120/120S, 160/160S as per ANSI B36.19/36.10 |

| End | Plain End, Beveled End, Treaded |

| Finish | No.1 Pickled Finish, No.4 finish, BA Finish, Electropolished Welded Pipes |

| Delivery Condition | Hot Finish, Cold Finish, Bright Annealed, Polished, Annealed and Pickled, Passivated, Stress Relived, As Welded, Welded & Externally Polished, Welded Annealed & Pickled, Welded Cold Drawn Annealed & Pickled, Welded Cold Drawn Annealed Pickled & Externally Polished |

| Test Reports | PMI Test Reports, EN 10204 3.1 Certificate, NABL Approved Lab Report on Chemical and Mechanical Properties, NDT or Other Test Reports, 100% X-Ray Welding Reports |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | Ti | Fe | |

| 304 | min. | 18.0 | 8.0 | |||||||||

| max. | 0.08 | 2.0 | 0.75 | 0.045 | 0.030 | 20.0 | 10.5 | 0.10 | ||||

| 304L | min. | 18.0 | 8.0 | |||||||||

| max. | 0.030 | 2.0 | 0.75 | 0.045 | 0.030 | 20.0 | 12.0 | 0.10 | ||||

| 304H | min. | 0.04 | 18.0 | 8.0 | ||||||||

| max. | 0.010 | 2.0 | 0.75 | 0.045 | 0.030 | 20.0 | 10.5 | |||||

| SS 310 | 0.015 max | 2 max | 0.015 max | 0.020 max | 0.015 max | 24.00 26.00 | 0.10 max | 19.00 21.00 | 54.7 min | |||

| SS 310S | 0.08 max | 2 max | 1.00 max | 0.045 max | 0.030 max | 24.00 26.00 | 0.75 max | 19.00 21.00 | 53.095 min | |||

| SS 310H | 0.04 0.10 | 2 max | 1.00 max | 0.045 max | 0.030 max | 24.00 26.00 | 19.00 21.00 | 53.885 min | ||||

| 316 | min. | 16.0 | 2.03.0 | 10.0 | ||||||||

| max. | 0.035 | 2.0 | 0.75 | 0.045 | 0.030 | 18.0 | 14.0 | |||||

| 316L | min. | 16.0 | 2.03.0 | 10.0 | ||||||||

| max. | 0.035 | 2.0 | 0.75 | 0.045 | 0.030 | 18.0 | 14.0 | |||||

| 316TI | 0.08 max | 10.00 14.00 | 2.0 max | 0.045 max | 0.030 max | 16.00 18.00 | 0.75 max | 2.00 3.00 | ||||

| 317 | 0.08 max | 2 max | 1 max | 0.045 max | 0.030 max | 18.00 20.00 | 3.00 4.00 | 57.845 min | ||||

| SS 317L | 0.035 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 18.00 20.00 | 3.00 4.00 | 11.00 15.00 | 57.89 min | |||

| SS 321 | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 17.00 19.00 | 9.00 12.00 | 0.10 max | 5(C+N) 0.70 max | |||

| SS 321H | 0.04 0.10 | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 17.00 19.00 | 9.00 12.00 | 0.10 max | 4(C+N) 0.70 max | |||

| 347/ 347H | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 17.00 20.00 | 9.0013.00 | |||||

| 410 | min. | 11.5 | ||||||||||

| max. | 0.15 | 1.0 | 1.00 | 0.040 | 0.030 | 13.5 | 0.75 | |||||

| 446 | min. | 23.0 | 0.10 | |||||||||

| max. | 0.2 | 1.5 | 0.75 | 0.040 | 0.030 | 30.0 | 0.50 | 0.25 | ||||

| 904L | min. | 19.0 | 4.00 | 23.00 | 0.10 | |||||||

| max. | 0.20 | 2.00 | 1.00 | 0.045 | 0.035 | 23.0 | 5.00 | 28.00 | 0.25 | |||

| Grade | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 304/ 304L | 8.0 g/cm3 | 1400 °C (2550 °F) | Psi 75000 , MPa 515 | Psi 30000 , MPa 205 | 35 % |

| 304H | 8.0 g/cm3 | 1400 °C (2550 °F) | Psi 75000 , MPa 515 | Psi 30000 , MPa 205 | 40 % |

| 310 / 310S / 310H | 7.9 g/cm3 | 1402 °C (2555 °F) | Psi 75000 , MPa 515 | Psi 30000 , MPa 205 | 40 % |

| 306/ 316H | 8.0 g/cm3 | 1400 °C (2550 °F) | Psi 75000 , MPa 515 | Psi 30000 , MPa 205 | 35 % |

| 316L | 8.0 g/cm3 | 1399 °C (2550 °F) | Psi 75000 , MPa 515 | Psi 30000 , MPa 205 | 35 % |

| 317 | 7.9 g/cm3 | 1400 °C (2550 °F) | Psi 75000 , MPa 515 | Psi 30000 , MPa 205 | 35 % |

| 321 | 8.0 g/cm3 | 1457 °C (2650 °F) | Psi 75000 , MPa 515 | Psi 30000 , MPa 205 | 35 % |

| 347 | 8.0 g/cm3 | 1454 °C (2650 °F) | Psi 75000 , MPa 515 | Psi 30000 , MPa 205 | 35 % |

| 904L | 7.95 g/cm3 | 1350 °C (2460 °F) | Psi 71000 , MPa 490 | Psi 32000 , MPa 220 | 35 % |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Choosing Stainless Steel Welded Pipes from Irfan Pipes and Tubes ensures high quality and durability, as these pipes offer excellent corrosion resistance and strength. Our commitment to exceptional service and reliable delivery guarantees customer satisfaction across various industrial applications. Our expertise in stainless steel products ensures you receive a top-tier solution tailored to your needs.

Irfan Pipes and Tubes, one of the largest suppliers of Stainless Steel Welded Pipes in Istanbul, Turkey, offers a comprehensive range of high-quality pipes and tubes suitable for various industrial applications. Their extensive inventory and commitment to exceptional service make them a go-to choice for stainless steel products in the region.

Yes, we offer custom sizes for Stainless Steel Welded Pipes to meet your specific requirements. Our team at Irfan Pipes and Tubes is committed to providing tailored solutions for all your Piping & tubing needs. For more details, contact us at sales@irfanpipes.com.

Irfan Pipes and Tubes’ Stainless Steel Welded Pipes find extensive use in industries that prioritize hygiene, durability, and corrosion resistance. In construction, they serve in structural frameworks, handrails, and various architectural applications. The chemical and petrochemical sectors utilize them for transporting corrosive fluids, acids, and gases. The food and beverage industries favor these pipes for sanitary pipelines, thanks to their easy-to-clean surfaces.

©2024 Irfan Pipes and Tubes . All Rights Reserved.