Home > Nickel Alloy > Nickel Alloy 200 Tubing

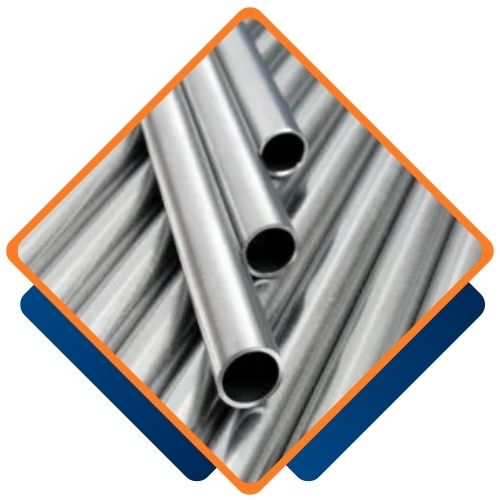

Irfan Pipes and Tubes in Istanbul, Turkey, is a reliable producer and supplier of top-class Nickel Alloy 200 tubing. With a reputation for specialty metal expertise, the company provides tubing solutions conforming to rigorous international standards and customer specifications. Nickel Alloy 200 tubing is globally known for its great corrosion resistance and mechanical properties, withstanding the harsh conditions of demanding industries. Irfan Pipes and Tubes guarantees accurate production and strict quality checking to deliver long-lasting, dependable tubing to chemical processing, aerospace, and marine applications industries, where performance and lifetime are paramount.

Nickel Alloy 200 tubes consist mainly of a minimum of 99% nickel and include traces of iron and other trace elements in minimal quantities. This almost pure nickel composition provides it with exceptional resistance to corrosive conditions of a broad spectrum, such as acids, alkalis, and sea water. Mechanically, it provides a tensile strength of around 480–690 MPa and excellent elongation of approximately 30%. The alloy has good ductility, toughness, and weldability even at cryogenic temperatures. Its corrosion resistance and stress corrosion cracking resistance make it suitable for high-strength applications under harsh conditions.

| ASTM B161 Alloy 200 Tubing Standards | ASTM B161/ ASME SB161, ASTM B725/ ASME SB725 |

|---|---|

| ASTM B161 Alloy 200 Seamless Tube Size | 3.35 mm OD To 101.6 mm OD |

| ASTM B161 Alloy 200 Welded Tube Size | 6.35 mm OD To 152 mm OD |

| ASTM B725 Nickel 200 Tubing Swg & Bwg | 10 Swg., 12 Swg., 14 Swg., 16 Swg., 18 Swg., 20 Swg. |

| Inconel WERKSTOFF NR. 2.4066 Tube wall thickness | 0.020″ –0.220″, (special wall thicknesses available) |

| Inconel UNS N02200 Tubing Length | Single Random, Double Random, Standard & Cut length Tube |

| Inconel WERKSTOFF NR. 2.4066 Tubing Finish | Polished, AP (Annealed & Pickled), BA (Bright & Annealed), MF |

| Form | ‘U’ bent, Hollow, Hydraulic, LSAW, Boiler, Straight Tube, Tube Coil, Round, Rectangular, Square Etc |

| Types of Nickel NW 2200 Tubing | Seamless, ERW, EFW, Welded, Fabricated Tube / Tubing |

| Nickel NW 2200 Tube End | Plain End, Beveled End, Treaded Tube |

| Marking | All ASTM B161 Nickel 200 Tubing are marked as follows: Standard, Grade, OD, Thickness, Length, Heat No. (Or according to the customer’s request.) |

| Application & uses of Nickel 200 Tube | Oil Tube, Gas Tube, Fluid Tube, Boiler Tube, Heat exchanger Tube, |

| Value Added Service | Draw & Expansion as per required Size & Length, Polish (Electro & Commercial) Annealed & Pickled Bending, Machining Etc. |

| Specialize in | ASTM B161 Nickel 200 Capillary Tube & Other Odd Size Nickel NCF 200 Heat Exchanger & Condenser Tube |

| Test Certificate | Manufacturer Test Certificate Laboratory Test Certificate from Govt. Approved Lab. Under Third Party Inspection |

| Nickel 200 | Ni | C | Mo | Mn | Si | Fe | P | S | Cu | Cr |

| 99.0 Min | 0.15 Max | – | 0.35 Max | 0.1 Max | 0.4 Max | – | 0.01 Max | 0.25 Max | – |

| Nickel Alloy 200 | ||

|---|---|---|

| Properties | Metric | Imperial |

| Tensile strength (annealed) | 462 MPa | 67000 psi |

| Yield strength (annealed) | 148 MPa | 21500 psi |

| Elongation at break (annealed prior to test) | 45% | 45% |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

| Density | 8.902gm/cc |

|---|---|

| Melting Point | 1453 oC |

| Boiling Point | 2732 oC |

| Thermal Conductivity | 0.909 W/cm/K @ 298.2K |

| Electrical Resistivity | 6.84 microhm-cm @ 20 |

| Electronegativity | 1.8 Paulings |

| Specific Heat | 0.106 Cal/g/ K @ 25 |

| Heat of Vaporization | 91.0 K-Cal/gm atom at 2732 oC |

| Heat of Fusion | 4.20 Cal/gm mole |

Choosing Nickel Alloy 200 Tubing from Irfan Pipes and Tubes ensures high quality and durability, as these tubing offer excellent corrosion resistance and strength. Our commitment to exceptional service and reliable delivery guarantees customer satisfaction across various industrial applications. Our expertise in nickel alloy products ensures you receive a top-tier solution tailored to your needs.

Irfan Pipes and Tubes, one of the largest suppliers of Nickel Alloy 200 Tubing in Istanbul, Turkey, offers a comprehensive range of high-quality pipes and tubes suitable for various industrial applications. Their extensive inventory and commitment to exceptional service make them a go-to choice for nickel alloy products in the region.

| Types of Nickel 200 Tube | Out diameter (OD) | Wall thickness | Length |

|---|---|---|---|

| NB Sizes (in stock) | 1/8” ~ 8” | SCH 5 / SCH 10 / SCH 40 / SCH 80 / SCH 160 | Upto 6 Meters |

| Nickel 200 Seamless Tube (Custom Sizes) | 5.0mm ~ 203.2mm | As per requirement | Upto 6 Meters |

| Nickel 200 Welded Tube (in Stock + Custom Sizes) | 5.0mm ~ 1219.2mm | 1.0 ~ 15.0 mm | Upto 6 Meters |

Yes, we offer custom sizes for Nickel Alloy 200 Tubing to meet your specific requirements. Our team at Irfan Pipes and Tubes is committed to providing tailored solutions for all your Piping & tubing needs. For more details, contact us at sales@irfanpipes.com.

Nickel Alloy 200 tubing is widely utilized in chemical processing plants, where corrosive chemicals such as hydrochloric and sulfuric acids are handled by it. It is also preferred in the marine environment for seawater piping and desalination equipment owing to its corrosion resistance against chlorides. In electronics and aerospace, Nickel Alloy 200 tubing is utilized in fuel systems, heat exchangers, and electrical equipment. It also has use in food processing and pharmaceutical applications where corrosion resistance and cleanliness are critical. The versatility of the alloy along with good mechanical and corrosion resistance characteristics makes it ideal for a wide variety of high-performance applications.

©2024 Irfan Pipes and Tubes . All Rights Reserved.